Super Ario Models

- Home

- Super Ario Models

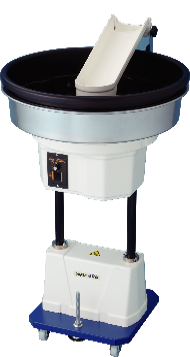

- SPA-500H

SPA 500H

$3,933.58

The tall model SPA-500H of the Dacon prevention / unmanned work collection device [Super Ario] is a device that collects and accumulates the finished work sent from the CNC automatic lathe without dents or scratches.

SPA-500H Tall Model Full Specifications

- The tall model SPA-500H of the Dacon prevention / unmanned work collection device [Super Ario] is a device that collects and accumulates the finished work sent from the CNC automatic lathe without dents or scratches.

- Unmanned driving is possible regardless of daytime and nighttime, and the repeat rate is high, and it is also adopted by major companies.

- Ideal when the position of the conveyor is as high as about 800 mm from the floor.

- SPA-500H is a tall (750 mm to 850 mm) model that fits the height exactly to the conveyor’s transport port to catch the finished product more safely and reliably.

- Catch the finished work in the center of the saucer, rotate it while rinsing it with a cleaning solution, and accumulate it.

- With septic tank, cleaning effect such as chip removal and oil removal, rust prevention effect.

- It is also possible to separate cutting oil from the work, collect cutting oil and recycle it.

- Installation Installation is very easy. Easy to move with casters.

- Unmanned driving is possible during the day and at night.

Equipment Specifications

Rating

Japanese model: AC100V 50 / 60Hz 25W

Bucket

Standard specifications φ500mm Depth 95mm

Rotational Speed

0.3-4.6rpm / 50Hz. 0.3-5.5rpm / 60Hz

Height to Shooter

750-850mm

Maximum Storage Load

25kg (including cleaning liquid)

Collectible Work Size

(Diameter) φ4 ~ 25mm (Length) Maximum 75mm

Product Dimensions

φ500 x (height) 750-850 mm (excluding protruding parts)

Detailed Outline PDF

Product Weight

20.3kg

Device Function

Work State

Dry state with cleaning liquid immersion or no liquid

Height Adjustment

Adjustment width 100mm

Work Supply and Alignment Direction

The workpieces that slide down on the shooter and are caught by the circular part of the shooter end are sequentially extruded from the center of the tray toward the outer circumference of the tray and aligned.

Speed Adjustment

With speed controller (There is a slight speed difference depending on the 50Hz.60Hz area)

Powered By EmbedPress

Get A Free Online Demonstration With Us

Can’t join us in person hit the play button to see the Super Ario in action, or click contact us to set up a virtual demonstration.

Premier North American Distributor of Super Ario.

Hotline : 1-715-824-3995

Phone

715-824-3995

Terickindustrial@gmail.com

Location

3401 Welton Dr.

Amherst Junction, WI 54407

Get on our mailing list for Super Ario news and updates.

Copyright © Melum Marketing 2023